The “Blow Down System: Design, Operation, and Safety” course is tailored to provide participants with a comprehensive understanding of blow down systems used in industrial processes. This course covers the design principles, operational procedures, safety considerations, and maintenance practices essential for managing blow down systems effectively in various industrial settings

- Understanding Blow Down Systems: Gain a thorough understanding of the principles and functions of blow down systems.

- Design Principles: Learn the key design considerations and criteria for effective blow down systems.

- Operational Procedures: Develop proficiency in the operational aspects of blow down systems, including startup, shutdown, and emergency procedures.

- Safety Considerations: Understand the safety protocols and risk management strategies associated with blow down systems.

- Maintenance Practices: Acquire knowledge on the maintenance and inspection of blow down systems to ensure their reliability and safety.

Introduction to Blow Down Systems:

- Definition and purpose of blow down systems

- Applications in various industries (e.g., oil and gas, chemical, power generation)

Design Principles:

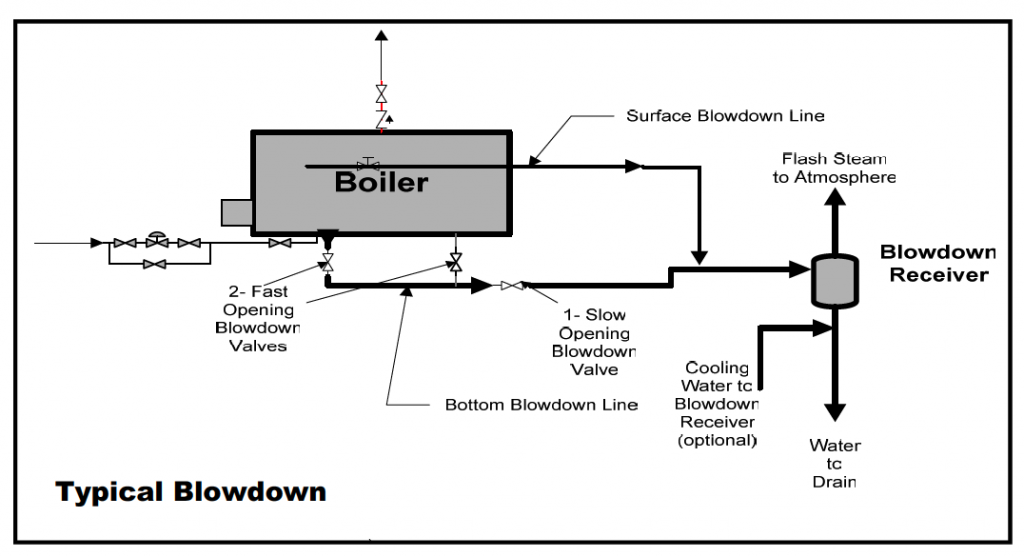

- Key components of blow down systems: valves, piping, drums, and vents

- Design criteria and considerations for blow down systems

- Sizing and selection of blow down system components

- Engineering standards and codes relevant to blow down systems

Operational Procedures:

- Normal operation of blow down systems

- Procedures for startup and shutdown

- Managing blow down during emergency situations

- Monitoring and controlling blow down parameters

Safety and Risk Management:

- Identifying potential hazards associated with blow down systems

- Implementing safety protocols and emergency response plans

- Pressure relief and venting safety considerations

- Risk assessment and mitigation strategies

Maintenance and Inspection:

- Routine maintenance practices for blow down systems

- Inspection techniques and frequency

- Troubleshooting common issues in blow down systems

- Documentation and record-keeping for maintenance activities

Environmental Considerations:

- Managing and minimizing environmental impact of blow down operations

- Regulatory compliance for emissions and effluents

- Best practices for environmentally responsible blow down operations

Case Studies and Practical Exercises:

- Real-world examples of blow down system design and operation

- Hands-on exercises in troubleshooting and maintenance

- Group discussions on best practices and lessons learned

By the end of this course, participants will:

- Have a comprehensive understanding of the design, operation, and safety considerations of blow down systems.

- Be able to design and select appropriate components for blow down systems.

- Develop operational proficiency in managing blow down systems, including emergency procedures.

- Understand and implement safety protocols to mitigate risks associated with blow down operations.

- Gain skills in the maintenance and inspection of blow down systems to ensure their reliability and compliance with regulations.

This course is suitable for:

- Process Engineers

- Mechanical Engineers

- Safety Officers

- Maintenance Technicians

- Plant Managers

- Operations Supervisors

- Anyone involved in the design, operation, or maintenance of blow down systems

Enroll Now

To enroll in the “Blow Down System: Design, Operation, and Safety” course, visit our course registration page or contact our course coordinator at [email protected]

Get In Touch!

Contact us for a quote or in case of any urgent queries please send us an email on: [email protected]

we will get back to you right away!