Menu

OrientMCT

Rotating Machinery Vibration Analysis

Rotating Machinery Vibration Analysis is a specialized course that focuses on the techniques and methodologies used to analyze and diagnose vibration-related issues in rotating machinery. Vibration analysis plays a crucial role in the maintenance and troubleshooting of various types of rotating equipment, including pumps, motors, turbines, compressors, and more.

The course covers the following key topics:

- Introduction to vibration analysis: Understanding the basics of vibration, its causes, and its effects on rotating machinery.

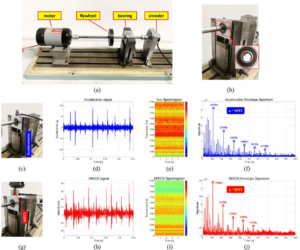

- Vibration measurement and instrumentation: Learning about different types of vibration sensors and instruments used for data collection, including accelerometers, proximity probes, and tachometers.

- Data acquisition and analysis: Exploring the techniques for acquiring vibration data and analyzing the collected data using software tools. This includes time domain analysis, frequency analysis, and waveform analysis.

- Fault diagnosis: Understanding how to interpret vibration data to identify common machinery faults, such as unbalance, misalignment, bearing defects, resonance, and looseness.

- Diagnostic techniques: Learning advanced vibration analysis techniques, such as orbit analysis, phase analysis, modal analysis, and shaft centerline analysis, to diagnose complex vibration problems.

- Condition monitoring: Understanding how vibration analysis is used as a predictive maintenance tool for continuous monitoring of rotating machinery health and early detection of potential failures.

- Vibration standards and best practices: Familiarizing with industry standards and best practices for vibration analysis, including ISO standards and recommended guidelines.

The course covers the following key topics:

- Introduction to gas turbines and compressors: Understanding the basic operation, components, and applications of gas turbines and compressors.

- Control system architecture: Exploring the structure and components of control systems used in gas turbines and compressors, including sensors, actuators, controllers, and human-machine interfaces.

- Control modes and strategies: Learning about different control modes, such as speed control, load control, and temperature control, and the corresponding control strategies used in gas turbines and compressors.

- Instrumentation and measurement: Understanding the types of sensors and instruments used to measure critical parameters such as temperature, pressure, flow rate, and vibration in gas turbines and compressors.

- Control algorithms and tuning: Examining the algorithms and techniques used to develop control algorithms for gas turbines and compressors, and the importance of proper tuning for optimal performance.

- Safety and protection systems: Exploring the safety and protection systems implemented in gas turbines and compressors, including overspeed protection, temperature limits, and emergency shutdown systems.

By the end of the course, participants will have a solid understanding of gas turbine and compressor control principles, enabling them to effectively operate, monitor, and troubleshoot control systems. This course is suitable for engineers, technicians, and operators involved in the operation and maintenance of gas turbines and compressors.

If you would like further information about this course or have any specific questions, please feel free to contact us directly or send us an email.!!!!!!!!

Get In Touch!

Contact us for a quote or in case of any urgent queries please send us an email on: [email protected]

we will get back to you right away!