Menu

OrientMCT

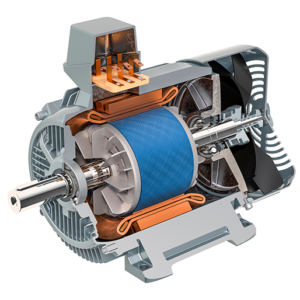

Single-Phase Motors

Single-phase motors are electric motors that operate on a single-phase power supply, which is commonly found in residential and small commercial applications. They are widely used in various devices and equipment, including fans, pumps, compressors, appliances, and power tools. Here are some key points about single-phase motors:

Types of Single-Phase Motors: There are different types of single-phase motors, including split-phase motors, capacitor-start motors, capacitor-start/capacitor-run motors, shaded-pole motors, and permanent split capacitor (PSC) motors. Each type has specific characteristics and applications.

Starting Mechanisms: Single-phase motors typically require a starting mechanism to initiate rotation. This is because a single-phase power supply alone cannot generate a rotating magnetic field. Starting mechanisms can include auxiliary windings, capacitors, centrifugal switches, or shaded poles, depending on the motor type.

Running and Starting Windings: Single-phase motors often have two windings: a main running winding and an auxiliary starting winding. The starting winding provides an initial boost to overcome inertia and start the motor. Once the motor reaches a certain speed, the starting winding is typically disconnected from the power supply.

Capacitors: Capacitors play a crucial role in many types of single-phase motors. They provide the necessary phase shift to create a rotating magnetic field, which allows the motor to start and run. Capacitors can be used in various configurations, such as in series with the auxiliary winding or in parallel with the main winding, depending on the motor type.

Starting and Running Torque: The starting torque of single-phase motors is typically lower compared to three-phase motors. However, some types of single-phase motors, such as capacitor-start/capacitor-run motors, can provide higher starting torque. Running torque is also a consideration when selecting a single-phase motor for a specific application.

Speed Control: Speed control of single-phase motors can be more challenging compared to three-phase motors. While some methods, such as using variable voltage or frequency drives, can enable speed control to some extent, it is generally more limited in single-phase motors.

Maintenance: Single-phase motors require regular maintenance, including periodic lubrication, inspection of capacitors, cleaning, and checking for any signs of wear or damage. Proper maintenance helps ensure optimal performance and extends the lifespan of the motor.

- Efficiency and Power Factor: Single-phase motors generally have lower efficiency and power factor compared to three-phase motors. This is due to the inherent limitations of the single-phase power supply and the need for additional components, such as capacitors, to create the rotating magnetic field.

It is important to consult the manufacturer’s specifications and guidelines for the specific single-phase motor in use, as different motor types and designs may have unique characteristics and operating requirements. Additionally, adhering to safety precautions and electrical codes is essential when working with single-phase motors to prevent accidents and ensure safe operation.

Get In Touch!

Contact us for a quote or in case of any urgent queries please send us an email on: [email protected]

we will get back to you right away!