Drilling High-Temperature and High-Pressure (HT/HP) Wells Technology

Drilling Engineering

Drilling High-Temperature and High-Pressure (HT/HP) Wells is a specialized area of drilling technology that focuses on drilling wells in extreme temperature and pressure conditions, often encountered in challenging environments such as deepwater, geothermal reservoirs, and ultra-high-temperature oil and gas formations. HT/HP drilling technology involves advanced equipment, materials, and techniques to ensure safe and efficient drilling operations.

Here are some key aspects of HT/HP drilling technology:

Wellbore Design and Planning: HT/HP wells require careful wellbore design and planning to withstand the extreme downhole conditions. This includes selecting appropriate casing and tubular materials, designing casing strings to withstand high pressure differentials, and considering thermal effects on wellbore stability.

Drilling Fluids and Mud Systems: Specialized drilling fluids and mud systems are used in HT/HP wells to maintain wellbore stability, control pressure, and provide lubrication and cooling in high-temperature environments. These fluids should have high thermal stability, low filtration rate, and adequate rheological properties to withstand the challenging conditions.

Downhole Equipment and Tools: HT/HP drilling requires the use of specialized downhole equipment and tools that can withstand extreme temperatures and pressures. This includes high-temperature drill bits, drill collars, drilling jars, and other bottom hole assembly (BHA) components designed for HT/HP applications.

Well Control and Blowout Prevention: Well control is of utmost importance in HT/HP drilling due to the potential for high-pressure formations and the risk of blowouts. Advanced well control techniques, such as managed pressure drilling (MPD) and underbalanced drilling (UBD), are utilized to control pressure and prevent well control incidents.

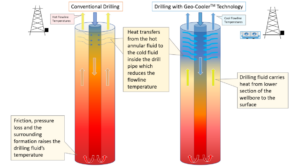

Temperature Management: Effective temperature management is crucial in HT/HP drilling to protect downhole equipment and maintain drilling efficiency. Techniques such as cooling the drilling fluid, using specialized insulation materials, and incorporating heat exchangers or coolers at the surface are employed to manage temperature effects.

Casing and Cementing: Selecting and designing casing strings for HT/HP wells requires considering the mechanical properties of the casing materials and their ability to withstand high pressure and temperature differentials. Cementing operations must also be carefully planned and executed to ensure zonal isolation and prevent casing failure or fluid migration.

Well Monitoring and Surveillance: Continuous monitoring and surveillance of HT/HP wells are necessary to ensure the integrity of the wellbore and identify any potential issues. Advanced technologies such as real-time downhole data acquisition, wellbore imaging, and temperature logging are used for monitoring and surveillance purposes.

Health, Safety, and Environmental Considerations: HT/HP drilling operations pose unique health, safety, and environmental challenges. Rig personnel should receive specialized training to handle the associated risks and implement safety protocols specific to HT/HP environments. Environmental considerations include proper handling and disposal of drilling fluids, management of high-pressure gas releases, and compliance with environmental regulations.

Drilling HT/HP wells requires a deep understanding of the technical challenges and specialized techniques associated with extreme temperature and pressure conditions. Professionals involved in HT/HP drilling operations, such as drilling engineers, wellsite supervisors, and drilling contractors, often undergo specialized training to gain the necessary knowledge and skills to execute drilling operations safely and efficiently in HT/HP environments.

Contact us for a quote or in case of any urgent queries please send us an email on: [email protected]

we will get back to you right away!