OrientMCT

Well Integrity Management

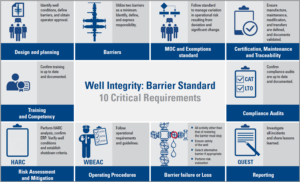

Well Integrity Management is a comprehensive approach to ensure the integrity and reliability of oil and gas wells throughout their entire lifecycle. It involves the implementation of strategies, practices, and monitoring systems to prevent, detect, and mitigate potential risks or issues that may compromise the integrity of the wellbore and surrounding formations.

The Well Integrity Management process begins during the planning and design phase of a well, where considerations are made to select appropriate well construction materials, casing and cementing programs, and wellbore design that can withstand the anticipated downhole conditions. This includes assessing the geomechanical properties of the formations, pore pressure analysis, and considering wellbore stability factors.

During well construction, proper casing and cementing operations are performed to provide a secure and fluid-tight barrier between the wellbore and the surrounding formations. Casing strings are installed and cemented to isolate different zones and prevent the migration of fluids, such as hydrocarbons or formation water, between the wellbore and the surrounding formations.

Throughout the course, participants will learn about various drilling methods and techniques used in the industry, including rotary drilling, directional drilling, and offshore drilling. They will explore the functions and components of drilling rigs, such as drill bits, drill pipes, and drilling mud systems, and understand their roles in the drilling process.

The course will cover essential concepts related to well planning and design, including wellbore stability, casing and cementing operations, and well control techniques. Participants will gain insights into the importance of geology in drilling operations, as they learn about formation evaluation, pore pressure analysis, and wellbore hydraulics.

Well Integrity Management also involves ongoing monitoring and maintenance activities throughout the production phase of the well. This includes regular inspections, integrity testing, and surveillance programs to detect and address any potential integrity issues, such as casing corrosion, cement degradation, or wellbore leaks.

Integrity management plans typically include preventive and corrective actions to maintain the integrity of the well. This may involve the implementation of corrosion protection measures, the use of well control equipment, and the establishment of monitoring systems to detect any changes in well conditions. In the event of an integrity failure or emergency situation, well control procedures and contingency plans are in place to mitigate risks and ensure the safety of personnel and the environment.

Additionally, well abandonment and decommissioning procedures are an essential part of Well Integrity Management. Proper plugging and abandonment operations are carried out to ensure that the well is permanently sealed and that there is no risk of leakage or environmental contamination.

Well Integrity Management is critical for the safe and efficient operation of oil and gas wells. It helps to minimize the risk of blowouts, uncontrolled releases of hydrocarbons, or environmental damage. By implementing proactive monitoring, maintenance, and risk mitigation measures, Well Integrity Management aims to ensure that wells remain structurally sound, secure, and compliant with regulatory requirements throughout their operational life

Get In Touch!

Contact us for a quote or in case of any urgent queries please send us an email on: [email protected]

we will get back to you right away!